I silkscreened an edition of 50 promo cards for the Vee modular tent design. Let me know via email if you'd like one.

5/5/12

4/29/12

Vee Modular Tents

I got some friends to help me test and photograph the final prototype of my tent design this past weekend. Named Vee for the distinctive v shape that allows multiple tents to connect. More photos and presentation material to come, hold tight!

4/23/12

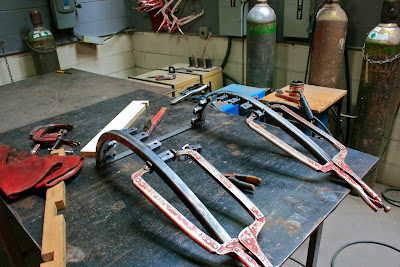

Furniture Fabrication

I just finished a freelance furniture fab job and thought I should share some photos of the process. The last shot shows the stools after they received a copper patina and right before they got clear-coated. Small wooden slats will nest inside both frames. All design work by Jenny Parker, final photos to come.

4/4/12

Sign Painting

3/29/12

Testing

I spent last weekend going for a ride to Harriman State Park to test my most recent tent prototypes with some friends. We were lucky enough to have beautiful, dry weather for the 50 mile rides up and back, however the tents were put to the test during the night's downpour. I am happy to say all our gear as well as ourselves stayed dry and relatively warm despite the lack of doors on my older prototype. We were also able to successfully pair the two tents, which gave the three of us plenty of room. The lightweight design was especially helpful on our backs due to our lack of panniers.

3/22/12

Ripstop Nylon Prototyping

My latest full-scale prototype has a few new additions including 2 doors, an elevated foot, and the ability to be pitched with two aluminum poles. So far the Ripstop has been doing a great job but I plan to do some wet weather testing this weekend about 60 miles outside of the city so I can look for failure points, design problems, and sizing adjustments.

Stay tuned for more photos of the tent in use as well as my first full-scale attempts at attaching multiple tents!

Prototype 41 person + gear

1.9 oz Polyurethane Coated Ripstop, nylon webbing, nylon thread, Seam Grip (water-proof seam-sealer)

18 oz (w/ nylon cord)

Stay tuned for more photos of the tent in use as well as my first full-scale attempts at attaching multiple tents!

Prototype 41 person + gear

1.9 oz Polyurethane Coated Ripstop, nylon webbing, nylon thread, Seam Grip (water-proof seam-sealer)

18 oz (w/ nylon cord)

SolidWorks Pattern Design

Testing Ripstop Nylon

After deciding that Tyvek is not quite durable enough to be used as a tent fabric, I have begun prototyping in Ripstop Nylon. Nylon is the standard material for rain-flys and tent-bodies, so it seemed like a good place to start. This prototype has an updated pattern to allow for more headroom inside the tent. Although this model seems to be about 6 inches short for someone my height, once doors are added it may be the perfect length.

Prototype 3

1 person + gear

1.9 oz Polyurethane Coated Ripstop, nylon webbing, nylon thread, Seam Grip (water-proof seam-sealer)

11.8 oz (w/out nylon cord)

1.9 oz Polyurethane Coated Ripstop, nylon webbing, nylon thread, Seam Grip (water-proof seam-sealer)

11.8 oz (w/out nylon cord)

Subscribe to:

Posts (Atom)